Get in touch with us

Measure air and surface temperature during an oven run with oven temperature logger PosiTest OTL

The oven temperature logger DeFelsko PosiTest OTL and PosiSoft software ensure optimal process control.

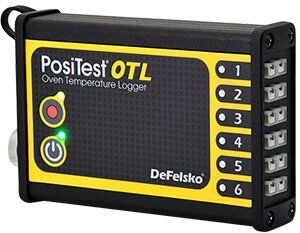

The DeFelsko PosiTest OTL Oven Temperature Logger is designed to measure and record air and surface temperatures while exposed to the extreme heat of oven operation. It measures and records up to 40,000 data sets. The PosiTest OTL is easy to use and comes with PosiSoft reporting software. It features 6 K-type thermocouple channels and a special stainless steel thermal protection box designed for long run times at high temperatures.

Why measure the oven temperature profile?

After the powder coating has been applied to a part, it must be held at elevated temperatures for a specified period of time in order for it to fully cure. Recording the oven temperature is important to ensure consistent quality and to ensure adequate curing over the entire surface of the part. Oven temperature loggers such as the PosiTest OTL are primarily used in the powder coatings industry, but are also used in a variety of other industries.

What is Oven Temperature Profiling?

Oven temperature profiling records temperatures at multiple locations on a part as it progresses through either a conveying or batch heating process. Temperature data is collected to optimize processes, minimize the cost of baking and curing powder coatings, and to ensure the oven is continuously operating properly. An undercured area of powder coating will not meet durability specifications, even if it looks no different to a cured one to the naked eye.

Creating a temperature profile for the oven can be done in four easy steps:

- Connect up to 6 temperature sensors to the data logger and the part under test. To ensure temperature is monitored throughout the part, it is recommended to place probes on thin, thick, high and low areas of the part and use at least one air temperature sensor. Put the data logger in the heat protection box. Send the data logger and the Test part in the oven. Analyze the results and create a report.

Temperature profiling is an effective way of minimizing energy consumption, improving product quality and useful for quick troubleshooting.

What is an oven temperature logger?

An oven temperature logger is a device optimized and configured to consistently measure temperatures using temperature sensors (thermocouples) and store the readings for reporting. The PosiTest OTL has 6 Type K thermocouple terminals (channels). When used in conjunction with the free PosiSoft Desktop Software, the measurement data can be easily imported into analysis software or spreadsheets to view and analyze the block data.

What is an oven temperature sensor (thermocouple)?

A furnace temperature probe (thermocouple) is a sensor used to monitor and record the temperature profiles of production furnaces, typically used for curing powder coatings and other industrial applications. Oven temperature probes can be inserted directly into an oven to record data that can later be downloaded to a computer for analysis. Real-time analysis of oven temperatures can help identify hot or cold spots in the oven before problems arise.

mtv messtechnik offers a wide range of air and surface temperature sensors for measuring furnace temperatures. Choose from spring clamp, magnet, or washer temperature probes with 1.8, 3.6, or 6 m (6', 12', or 20') braided stainless steel cables to probe air or surface temperatures for your application.

- Clamp-on surface probes for attachment to parts of different sizesMagnetic circulating air or surface probes that have a strong magnet for attachment to steel partssurface probes with a small magnet

Which models of the DeFelsko PosiTest OTL and Grant oven temperature loggers does mtv messtechnik offer?

mtv messtechnik offers two oven temperature logger sets from DeFelsko:

The PosiTest OTL Set and the PosiTest OTL XT Set.

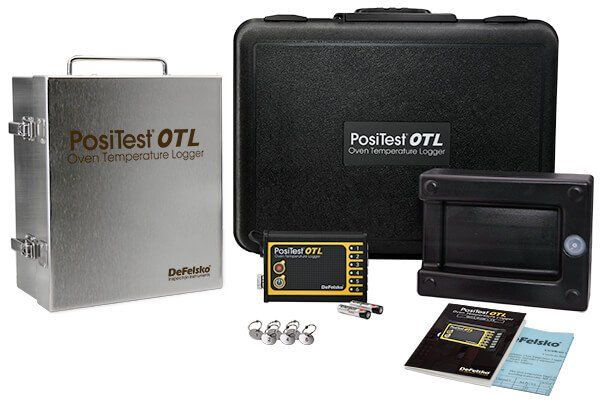

- The PosiTest OTL Set comes with an oven temperature logger, a stainless steel heat protection box with fiberglass insulation, a standard cradle without a cooling element, 6 engraved probe ID tags, and a carrying case.

- The PosiTest OTL XT Set contains everything from the PosiTest OTL Set and also a special XT cooling element for higher endurance at high temperatures

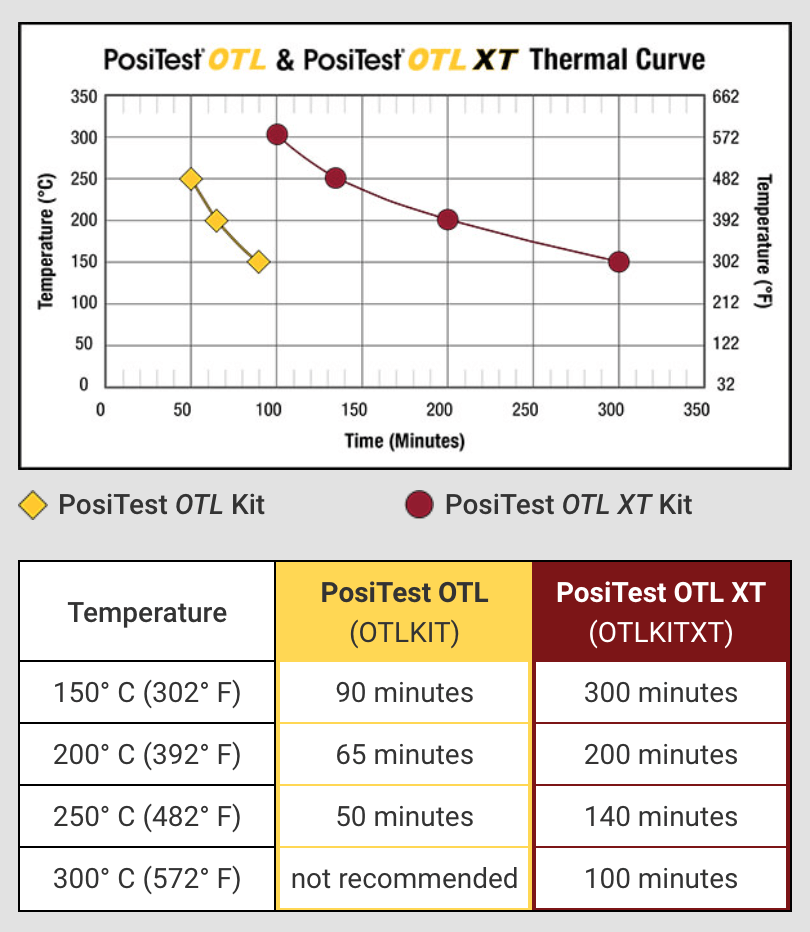

The graph and table above show the combined thermal characteristics of the PosiTest OTL Oven Temperature Logger, Thermal Shield Box and Heatsink or XT Heatsink.

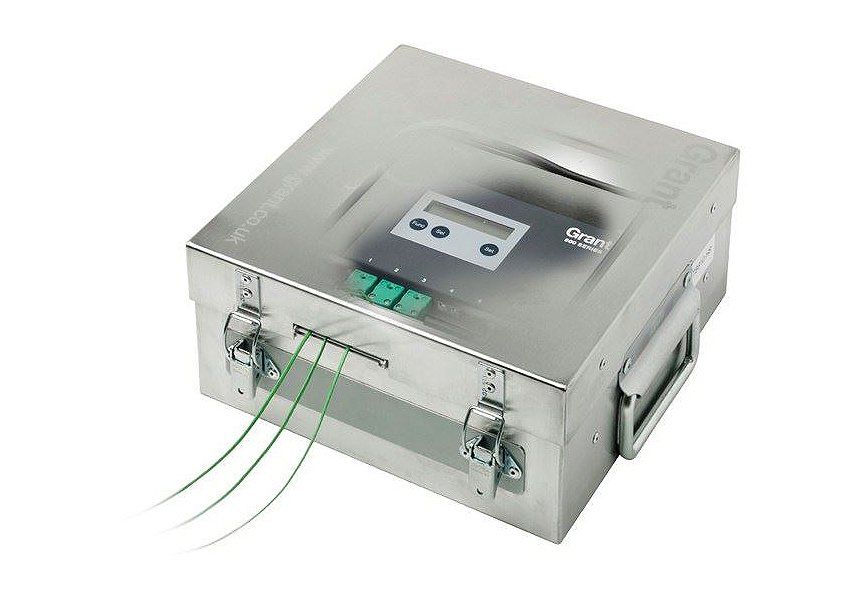

There are also two high-quality oven temperature logger sets from Grant in Cambridge, UK:

- Grant OMK 610 Oven Temperature Data Logger Kit Standard

- Grant OMK 610 Oven Temperature Data Logger Kit Advanced with increased heat protection performance

How is PosiSoft software used to log oven temperature?

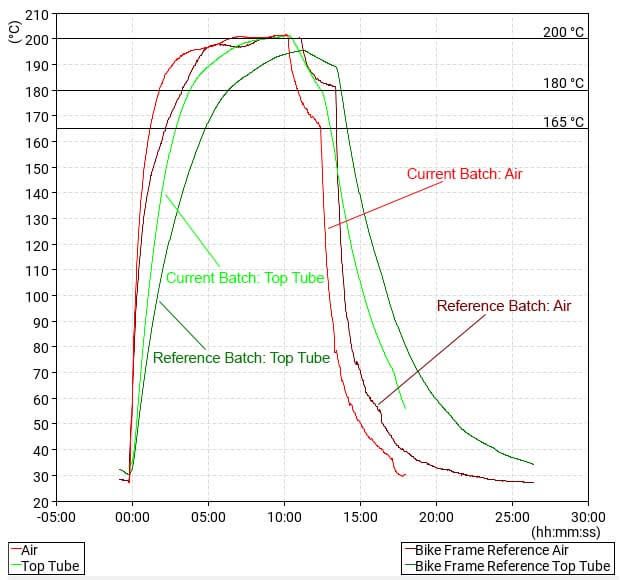

Powder coating manufacturers often specify some parameters that are required for full curing. In addition to ensuring uniform temperatures throughout the oven, the "time above temperature level" is an important parameter, as well as the time the coating must be held above a certain temperature in order to fully cure. The time above temperature value can be calculated simultaneously for up to three threshold temperatures as shown below.

PosiSoft Desktop Software not only allows the user to set up to three threshold temperatures to verify sufficient 'time at temperature' for each probe, but can also graph batch data along with a 'reference sample' from a previous batch, giving a allows instant comparison between batches as shown in the figures below.

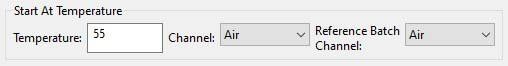

Because the amount of time between turning on the logger and placing it in the oven can vary, the "Start at temperature" option will set the elapsed time to zero when a selected probe exceeds a certain temperature - this corresponds to the time the logger is in is brought into the furnace. In the figure above, the "Start at temperature" value for the reference and current batch is 30°C.

The primary purpose of monitoring and maintaining the oven temperature is to verify that the oven is at and maintaining the specified temperature(s). Equally important is the monitoring of process conditions in the furnace to improve product quality control, reduce energy consumption and therefore costs, and increase productivity.

Why should I use a PosiTest OTL oven temperature logger?

The PosiTest OTL has an easy-to-use interface and records readings every 2 seconds, allowing for up to 22 hours of recording time. It can graph temperature readings from up to six sensors/channels to show temperature change over time. Current, graphically displayed measured values can be compared with previously saved reference profiles. Each channel plotted is color coded for easy identification and comparison. Users can easily create professional reports containing all the relevant information for the user's specific application.

Up to 6 type K thermocouple probes can be connected to the PosiTest OTL oven temperature logger.

Various clamp circulating air and surface sensors as well as magnetic circulating air and surface sensors with various cable lengths are available for measuring air and surface temperatures.

A high-temperature heat protection box made of stainless steel with fiberglass insulation and a cooling element of your choice enable long run times at high temperatures (up to 300 °C) for up to 300 minutes*. The PosiTest OTL has built-in memory for 40,000 sets of data (240,000 readings) that can be imported into PosiSoft Desktop, allowing users to create customizable reports.

*Thermal properties are dependent on temperature, time and kit configuration. Check out the table and chart in the Sets section of the PosiTest OTL page.

Contact info@mtv-messtechnik.de if you have any questions or would like to request additional information.

Business hours:

Monday - Thursday from 8:30 a.m. to 5 p.m. and Friday until 3 p.m

Justus-von-Liebig-Strasse 17a

50374 Erftstadt (Gymnich), Germany

+49 2235 987170

info@mtv-messtechnik.de