Surface inspection gages for FROSIO inspectors:

Adhesion testers, corrosion protection, coating thickness gages, Porosity Detection and more

What is a FROSIO inspector? A brief introduction

A FROSIO inspector is a certified professional in the field of surface inspection and protective coating. FROSIO (The Norwegian Professional Council for Education and Certification of Inspectors for Surface Treatment) offers globally recognized certifications for inspectors working in the field of corrosion protection and surface preparation. The main task of a FROSIO inspector is to ensure quality and compliance with standards in the coating and protection of surfaces.

Duties of a FROSIO inspector:

1. Surface preparation and cleaning: Checking surfaces for cleanliness and suitability for coatings.

This includes identifying and documenting contamination, rust and old coatings.

2. Coating testing: Monitoring and testing of applied coatings for thickness, adhesion and uniform distribution.

This may require the use of coating thickness gauges, tensile adhesion testers (adhesion testers) and other special measuring devices.

3. Visual inspection and defect detection: Visual inspection of surfaces and coatings to identify and document defects such as blistering, cracking, peeling and other defects.

4. Reporting: Prepare detailed inspection reports that document all identified deficiencies, deviations, and recommended corrective actions. Reports are often required for quality assurance and to demonstrate compliance with standards.

5. Communication and collaboration: Working closely with clients, engineers and other professionals to ensure that requirements and specifications are met. This includes attending meetings and advising on best practices and techniques.

Why are FROSIO inspectors so important?

FROSIO inspectors play a critical role in ensuring the longevity and reliability of coatings, especially in industries such as oil and gas, marine and construction. Their expertise helps prevent costly damage from corrosion and other surface problems.

The most important inspection instruments for FROSIO inspectors

FROSIO inspectors require and use a variety of specialized inspection instruments to perform their tasks efficiently. These include:

- Coating thickness gauges: These devices measure the thickness of coatings and ensure that the coatings meet specifications. High-quality testing devices of this type are the DeFelsko PosiTector 6000 coating thickness gauge for metal substrates according to ISO 2178 / 2360 / 2808. PosiTector 200 for non-metal substrates, as well as the PosiTest PC Powder Checker, an Ultrasonic, non-contact uncured powder thickness gage.

- Adhesion testers: Devices such as the PosiTest AT, an automatic adhesion tester, test the adhesion of the coating to the surface.

- Holiday Testers or Porosity Detectors: Equipment such as the DeFelsko PosiTest LPD Low Voltage and PosiTest HHD High Voltage DC Porosity Detector detect and locate pinholes and other defects in the coating that can lead to premature failure.

- Surface Profile testers: Devices such as the DeFelsko PosiTector RTR and -SPG are roughness and surface profile testers according to ASTM D 4417-B, US NAVY NSI 009-32, ISO 8503-5. They measure the roughness of the surface before coating to ensure that it meets norms and standards.

- Through the expert use of our professional measuring devices, FROSIO inspectors ensure that a coating meets the highest quality standards.

- Are you looking for professional measuring devices for FROSIO inspectors? mtv messtechnik offers a wide range of high-quality and reliable devices that have been specially developed for the demanding requirements of surface inspection.

- Contact us today for further information and individual advice!

- mtv messtechnik offers the complete range of necessary measuring instruments. The most important other devices include:

- Moisture meters: Meters such as the DeFelsko PosiTector DPM dew point meter according to ISO 8502-4 and the PosiTector DPM-L dew point data logger measure the dew point and moisture content of substrates to prevent coating defects due to inadequate surface preparation.

- Visual inspection instruments: These include inspection mirrors, microscopes or endoscopes for a detailed visual inspection of the surface condition.

- Corrosion testing equipment: Corrosion measuring instruments to assess the degree of corrosion resistance of coatings and substrates.

- Using our equipment, FROSIO inspectors can, for example, accurately assess surface quality, check coating quality and ensure the durability and performance of protective coatings.

Information on the requirements for self-testing according to DIN EN 1090 as well as instructions for self-testing according to DIN EN 1090 can be found here!

Measuring and testing equipment for FROSIO inspectors. We've got you covered and offer everything you need!

- Magnetic induction: For ferromagnetic substrates. Eddy current: For non-ferromagnetic substrates.

- Pull-off testers: Measures the adhesion strength of the coating to the surface. Cross-cut testers: Tests adhesion by cutting grid lines into the coating.

3. Porosity or holiday detectors

- Low voltage porosity detector: Detecting pinholes and holidays in non-conductive coatings. High voltage porosity detector: For thicker and more conductive coatings.

4. Roughness, Surface profile gages

5. Climate monitoring, dew point meters

- Thermohygrometers: Measure temperature and humidity. Dew point meters: Determine the dew point and relative humidity conditions.

6. Visual inspection devices

- Magnifying glasses/loupes: For detailed visual inspection. Flashlights: Illuminate hard-to-reach places and dark areas.

- Salt test strips: Determine the chloride content on surfaces. Conductivity meters: Measure the conductivity and indirectly the salt content.

8. Surface profile measuring instruments

- Testex Tape: Measures the profile of blasted surfaces.Calibration foils and standards: Ensure the accuracy of measuring instruments.

9. Microscopes

- Digital microscopes: High-resolution imaging and documentation of surface structures.Portable microscopes: For on-site use.

10. pH meters

- Digital pH meters: Precise measurement of the pH value on surfaces.

This comprehensive list of required measuring and testing equipment ensures that FROSIO inspectors can carry out precise and reliable inspections.

mtv messtechnik offers a range of high-quality measuring instruments specifically designed to meet the highest standards in surface inspection.

Contact us for further information and individual advice on our products!

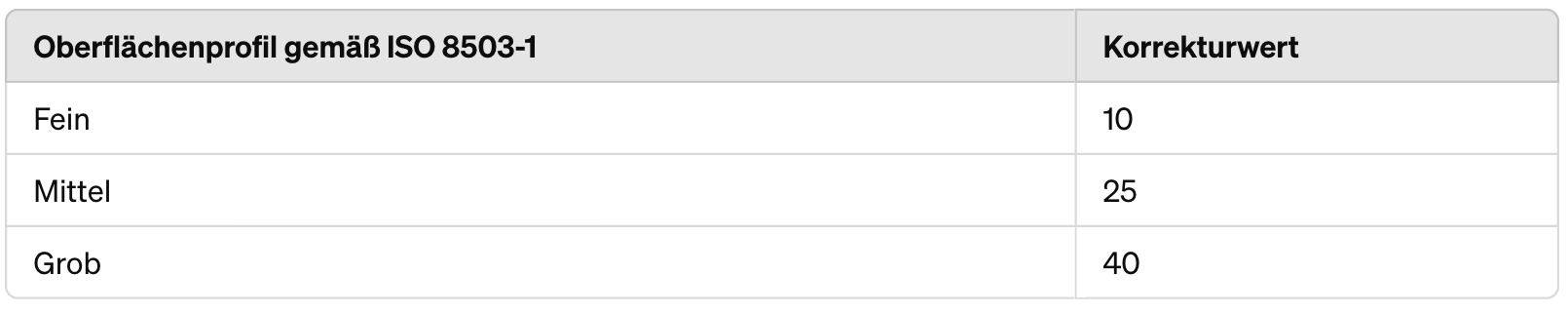

Here is a table showing the deviation in layer thickness according to DIN EN ISO 12944. This standard deals with the corrosion protection of steel structures using coating systems and defines the permissible deviations in layer thickness.

Deviation of layer thickness according to DIN EN ISO 12944 on smooth substrates

| Minimum dry film thickness (μm) | Single layer tolerance (%) | Total layer tolerance (%) |

|---|---|---|

| 0 - 60 | ± 20% | ± 15% |

| 61 - 120 | ± 15% | ± 10% |

| 121 - 250 | ± 10% | ± 7,5% |

| > 250 | ± 7,5% | ± 5% |

- The average value of all measurements must be at least equal to the agreed target layer thickness. All individual values of the dry layer thickness must be at least 80% of the target layer thickness. A maximum of 20% of the measured values may be less than the target layer thickness.

What this means specifically for the user:

- For a target layer thickness of 100 µm, no individual value may be less than 80 µm. The average value of the measurements may not be less than 100 µm. With five measuring points, only one measuring point may be between 80 and 99 µm

For rough surfaces, DIN EN ISO 12944-5 in conjunction with ISO 19840 applies

If this set of rules is the subject of the contract, the layer thickness measurement is agreed without layer thickness allowances for rough substrates.

For substrates of unknown roughness (see Table 2), a corresponding value must be deducted. In practice, this value is called a correction factor or correction value.

Note:If roughness is not known or no sample is available, a correction value of 25µm is applied.

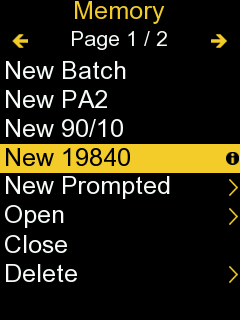

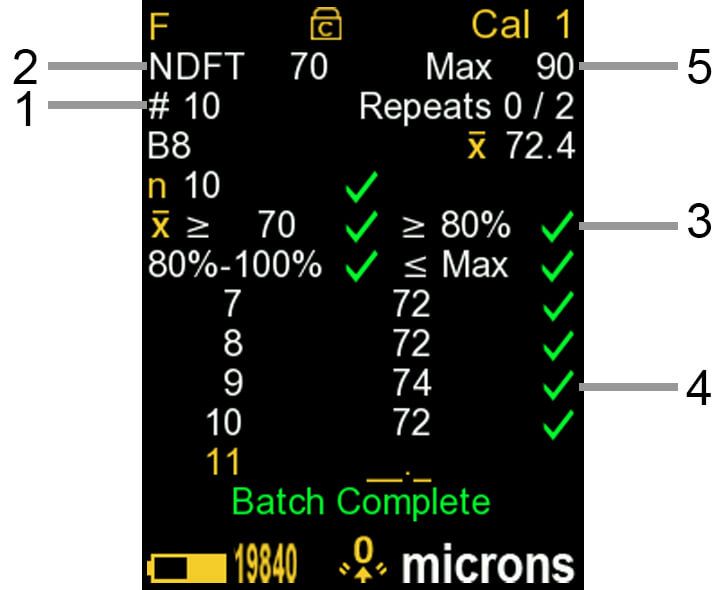

Using the ISO 19840 mode of the PosiTector 6000:

(including documentation of all required parameters)

- Switch on PosiTector 6000, then...

- Select 19840 mode

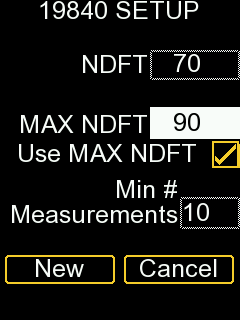

- 19840 Enter setup according to specifications

Start measuring on the coated surface & immediately receive all information on the display

The following happens with each measurement:

- The meter will beep twice (if the sound is enabled in the setup menu) and the current reading will be displayed next to the corresponding reading number.The block information will be updated with a pass or fail mark based on the following ISO 19840 requirements:

- The minimum number of measurements specified in the sampling plan shall be takenThe average of all individual dry film thicknesses shall be equal to or greater than the nominal dry film thickness (NDFT)All individual dry film thicknesses shall be at least 80 % of the NDFTIndividual dry film thicknesses between 80 % of the NDFT and the NDFT are permitted provided that the number of such measurements is less than 20 % of the total number of individual measurementsAll individual dry film thicknesses shall be less than or equal to the declared maximum dry film thickness, if declared.

You can buy the standard text here: – ISO – ISO 19840:2012 – Paints and varnishes — Corrosion protection of steel structures by protective coating systems — Measurement and acceptance criteria for the thickness of dry films on rough surfaces